Time for a long overdue update. I've been plugging away, bit by bit, but managed to get a good amount of hours in over the weekend, so made some good steps.

The right side of the cross rail has now been welded in, but I forgot to get a picture so I will have to get one at a later stage. Once that was in I was able to start trial fitting the tail panel. I was pleased to find that with the panel was able to squeeze in with the upper filler pieces attached (although only because the lower part of the left quarter panel is loose and can be swung to the left to make room). A little bit of wiggling and clearancing was required, but I did eventually get it into place and was able to start working out where the spot welds would be needed.

I should have taken some pics from the inside, as the panel didn't conform to the trunk panel as well as I'd hoped and it was clear it would need to be pulled in at a number of places. As this could then affect the fit of the whole panel, I opted to get the screws out and firmly attach the panel and pull it into place. As you can see, some of my estimates on where to drill holes were a bit off!

With the tail panel in it's final location, I was able to move back inside the trunk and start working on the patch for the floor. No pics, but I trial fitted the drop off, clamping it to the wheelhouse and a screw to the tail panel, giving me the outer boundary for the patch. I mocked up a cardboard template, then cut and folded a section from the old quarter panel into a rough shape. After lots of fettling, it was an acceptable fit (for now!)

Whilst clamped in place I marked the outline of the frame underneath, and then used this as a template to drill the holes ready for welding.

Again, no pics (I'm slipping

), but I now had to cut out one of the trunk reinforcement pieces, ready to fit to the patch. Not sure if I bent it whilst removing, whether the patch isn't quite right, or the frame isn't welded in the right place (I hope not!) but I couldn't get the holes to get close to the holes in the tail panel. After about an hour of pulling, pushing, hammering and bending, I gave in and simply cut the ear off and welded it back on 1/2 inch lower down.

With this now fitting I refitted bumber and bolted it up, only to find it pulls the patch quite a bit and it's too short (no pics again, but you'll see it later). I will need to patch a thin strip across the top later on.

Holes on the patch were then cleaned up, holed added to the side part and the patch was welded to the drop off (far easier than trying to attach the drop off in-situ)

And here's the top side

This was carefully clamped into place and a small bit of the trunk patched. The reinforcement piece bolted in to hold everything in place, then I welded into place at the drop off/wheelhouse joint

Then, inside the trunk I welded up the holes that were not hidden by the reinforcement piece and just tacked the edges to hold the patch down when the reinforcement was removed.

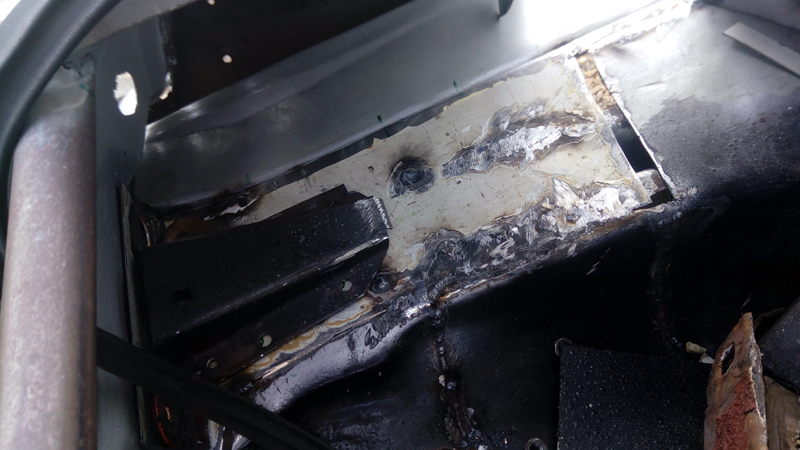

When I removed the reinforcement I discovered I had some poor penetration on some of the welds, due to the thicker metal of the frame. I had to cut out a couple of the welds and re-do them on a higher heat setting. I also unscrewed and removed the tail panel to give me better access to the rear most set of welds.

Rain and lack of welding gas put a stop to proceedings at this point. When I get some more gas, the next steps will be to fill the strip at the top of the patch and then I can clean up all the welds and weld in the reinforcement.