Seam sealed the cowl panel today, so its ready for top coat when the weather warms up (so that will be next year then!)

Then started cleaning up the plastic vent panel which had quite a few badly done coats of paint on it. Took ages, but its now bare plastic again. Might give it a light coat of satin black paint when I do the cowl, as its not in the best condition on close inspection. I know repro's are available, but then this isn't a show car.

As it was so cold, I decided to do some work inside, which mean making a start on the heads. Stripped the valves out, they all seem to be in good condition and are lightweight stainless items from what I can make out. Not sure what the springs are, they look like stock ones to me, so I'll probably change them for beehives while I am there.

Took a wire brush to the ports to see what had been done to them. Looks like they have just had most of the casting marks cut out with a carbide burr. No major reshaping that I can see...so thats another job to do.

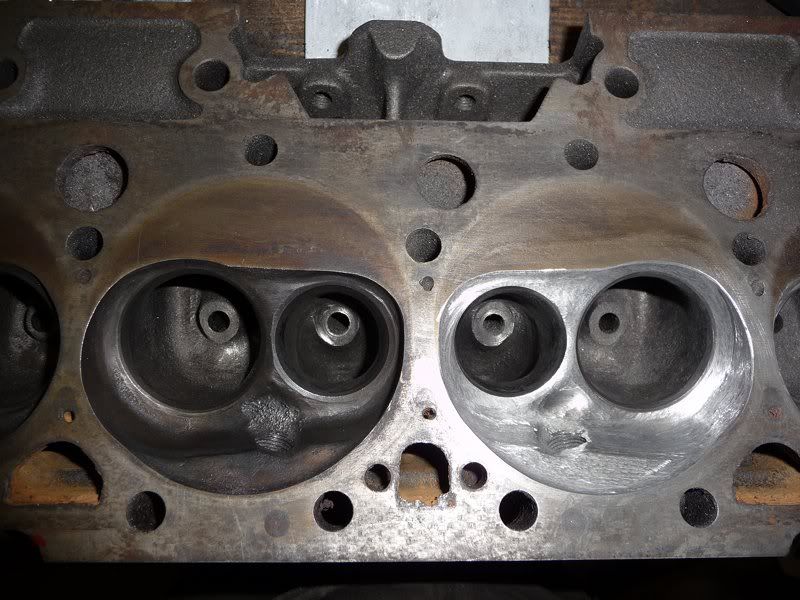

Started off with cleaning up the combustion chambers, deshrouding the valves and removing all the sharp edges. I am not going to the extent of polishing them, as there's bigger benefits to be had in some port and valve reshaping... Hopefully I will get on to some of that stuff tomorrow.

Heres a comparison shot

There is plenty of material to come out of the valve throats, this is the narrowest part of the port anyway, so the biggest gains are in opening that area out and blending into the valve seats, over any work closer to the manifold areas of the ports. I reckon its going to take about 8-10 hours per head. But we will see how it goes tomorrow.

This will be the first set of SBC heads I have ported, but I have done several other engines in the past with decent enough results so we'll see how I get on with these.

_________________

My '80 progress thread - hugger orange!

Now with LQ9 power - forged pistons, LS2 rods, 236/242, .621/.612, flowed and milled 317 heads. MS3X

4L80e, 12 bolt, 4.11, Moroso brute strength posi, steel shafts.

Subframe connectors, g-braces, solid body bushes, carbon hood and front bumper, custom door cards, Autometer gauges.